The well-tried and true meets high tech – fine-ceramic components in wafer productio

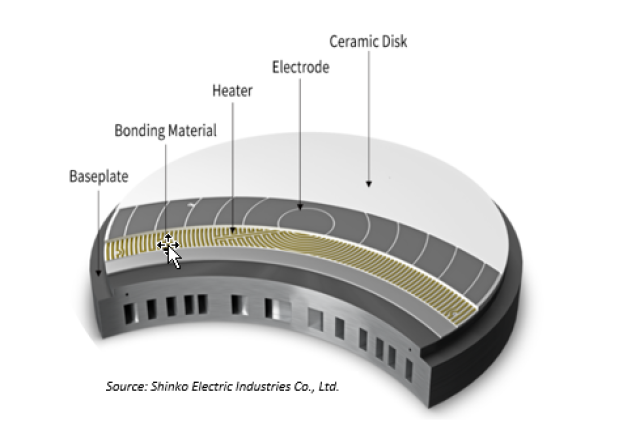

Once again, we dare to leave our comfort zone to discover new territory. The demand for electronic components requires a worldwide expansion of chip manufacturing, resulting in increased wafer production. René Gerber AG is in the process of establishing itself as an important link in the wafer production supply chain. Our attention is especially focused on microelectronic and microsystem elements such as the so-called "Electrostatic Chucks".

Electrostatic Chucks (ESC) are clamping devices used to hold wafers in place for further processing by means of electrostatic attraction forces. The ceramic cover plates of these chucks are the focus of our attention. Decisive criteria for the successful use of electrostatic chucks are their perfect flatness combined with minimum surface roughness (Ra < 0.05).

Only a first-class surface finish optimizes the chucking and de-chucking performance of the wafer clamping devices. It leads to higher wafer throughput and, thus, to increased production efficiency.

With our BP Mx brush polishing machine and the use of our in-house polishing paste, we polish the ESC surfaces to the best quality according to the criteria applicable to wafer production: perfect flatness with minimal surface roughness - Our well-tried paste polishing process meets a high-tech application in the semiconductor industry - Adaptability is the key to success!